Wind Turbine Blade

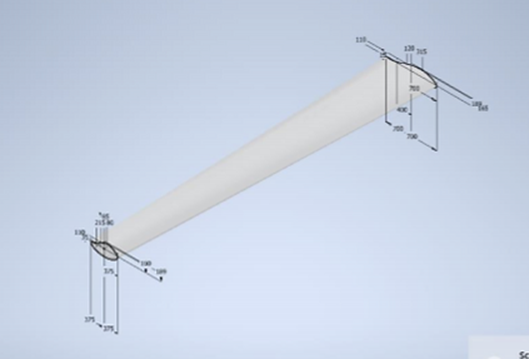

My first engineering project at McMaster University was an exciting and challenging endeavor that involved designing a wind turbine blade. It marked the beginning of my academic journey in the field of engineering and introduced me to various essential concepts and tools. Using Autodesk Inventor, I delved into the world of computer-aided design (CAD) for the first time. The software provided me with the means to transform my creative ideas into precise and detailed 3D models, allowing me to visualize the wind turbine blade's design and iterate on improvements effectively.

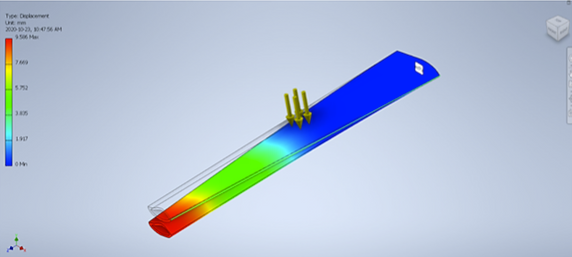

Additionally, the project introduced me to the world of Finite Element Analysis (FEA), a powerful simulation technique used to analyze the structural behavior of complex designs under different conditions. I applied FEA to assess the structural integrity of the wind turbine blade, ensuring it could withstand the forces and stresses experienced during operation. This knowledge was invaluable in making informed design decisions, ensuring that the final blade design would be safe, reliable, and efficient.

The project also taught me the importance of interdisciplinary collaboration. I worked closely with peers and faculty members, seeking advice and feedback to refine my design and gain insights from different perspectives. This experience enhanced my communication and teamwork skills, laying the foundation for successful collaboration on future projects.

Overall, my first engineering project at McMaster University was a significant milestone in my academic and professional journey. It sparked my passion for engineering, exposed me to CAD software and FEA, and cultivated essential skills that have since become crucial in my engineering pursuits.

Very first engineering project

What?

During my project, I optimized a wind turbine blade by carefully selecting materials and conducting structural analysis. The goal was to enhance efficiency and durability. The final design demonstrated improved performance, contributing to sustainable energy generation. This experience heightened my technical expertise and deepened my commitment to environmental stewardship.

How?

-Used Autodesk Inventor to design the wind turbine blade

-Used Ashby chart on Granta to determine the optimal material choice

-Performed failure analysis (FA) to determine weak points

Final Results

Through the optimization of the wind turbine blade, I achieved significant improvements in both efficiency and structural integrity. Meticulous material selection and thorough failure analysis guided the design enhancements, resulting in better performance and increased reliability. These advancements played a pivotal role in enhancing the overall efficiency of the wind turbine system, contributing to higher energy output and sustainability. This project deepened my understanding of the intricate interplay between materials, design, and performance in renewable energy systems. It bolstered my engineering skills and solidified my dedication to developing environmentally conscious solutions for a greener future.